INDUSTRIAL

TRAINING REPORT

Training

Taken at:

LAKSHMI

MACHINE WORKS Ltd, COIMBATORE

&

SIMTA Ltd,

COIMBATORE

SUBMITTED

BY

SATHYA PRAKASH.G

2K2-177

DEPARTMENT OF MECHANICAL ENGINEERING

NATIONAL INSTITUTE OF TECHNOLOGY

KURUKSHETRA

INTORDUCTION:

In

this modern world we are seeing computers and electronics have taken a lead

role in the development of a country. Computers are able to do any cumbersome

work in an easy way. In the same way, Computers are playing a significant role

in the machining process. This resulted in the Computerised Numerical Control

(CNC) operations of Lathe, Vertical Machining Centre (VMC) and Horizontal

Machining Centre (HMC).

These computerized operations have reduced costs involving in the

production by reducing number of workers, time involved in the production. This

also facilitates the quicker supply of products to customers.

ADVANTAGES OF CNC OVER NC:

For the majority of NC users, NC is about

productivity and flexibility - making a lot of parts, and many different parts,

on one machine tool. This was true even before computer numerical control (CNC)

superseded an earlier generation of machine tools that did not have the benefit

of microprocessor-based control technology. Today's CNC machines are flexible,

productive and capable.

What makes CNC so flexible and productive

is the ability to run different workpiece programs. With the right program,

machining is a pushbutton affair. Provided that the proper cutting tools and

setup fixtures are available, all a CNC machine needs to begin automatically

machining a new and different workpiece is a new and different program.

How to create those new and different

programs has taken various approaches. Many CNC machines can be programmed on

the shop floor, with the operator entering data at the control panel. This

method has been very popular, especially for simpler workpieces. Programs can

also be prepared "off-line," away from the machine tool, using

computer-aided manufacturing (CAM) software. This method is most often used for

more complex workpieces. However, the latest CAM software for the PC (personal

computer) provides many automated features that make NC programming largely a

pushbutton affair, regardless of how simple or complex the workpiece might be.

MACHINE SHOP

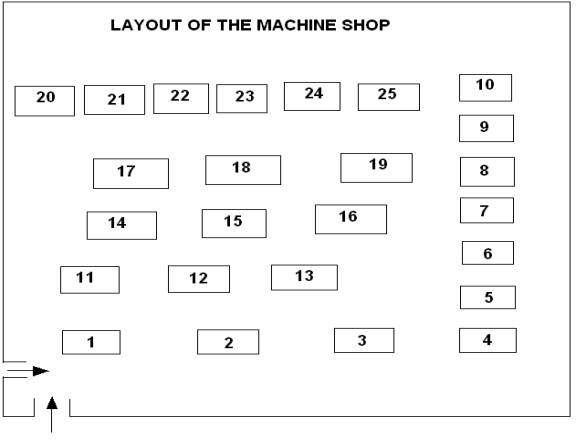

LAYOUT OF THE MACHINE SHOP:

When we have number of machines in a factory, only layout of the factory can give a clear idea about the machines available and arrangement of these machines. So I have prepared the layout of the Lakshmi Machine Tool Divisionís Machine Shop.

1. PLANO MILLER

2. SURFACE GRINDING MACHINE (NC)

3. HARDENING MACHINE

4. CNC LATHE

5. CNC LATHE

6. VERTICAL MACHINING CENTRE

7. VERTICAL MACHINING CENTRE

8. VERTICAL MACHINING CENTRE

9. VERTICAL MACHINING CENTRE

10. CNC

LATHE

11. UNIVERSAL MILLING MACHINE

12. RADIAL DRILLING

13. RADIAL DRILLING

14. HORIZONTAL MACHINING CENTRE

15. SURFACE GRINDING

16. SURFACE GRINDING

17. VERTICAL MACHINING CENTRE

18. HORIZONTAL MACHINING CENTRE

19. HORIZONTAL MACHINING CENTRE

20. VERTICAL MACHINING CENTRE

21. DEEP HOLE DRILLING MACHINE

22. LATHE (NC)

23. HONING

24. KEYWAY BROACHING

25. LATHE (NC)

DIFFERENCE BETWEEN LATHE AND MILLING

MACHINES:

The main difference between a lathe and a mill is that on a lathe, the work turns and the cutting tool is stationary, while on a mill, the tool turns and the work is stationary. Because of the tremendous number of operations that can be performed on a vertical mill, it is commonly regarded as the most important machine in the modern machine shop. At first glance a vertical mill looks similar to a drill press, but there are some important differences, such as a spindle that can take side-loads as well as end loads and an accurate method of moving the work in relation to the spindle on all three axes.

Operations such as milling, fly cutting, precision drilling, and boring are all routine tasks for the milling machines. Because the tool turns rather than the work, much larger parts may be worked on in a mill (these parts need not be round). The work is securely held, thus extremely accurate hole patterns can be drilled or bored using the vertical mill. The longer "X-axis" throw also increases the machine's versatility over that of the Lathe with the vertical milling column attachment. It is an extremely rigid, accurate tool which accomplishes tough machining jobs with ease.